Chapter 12: Is it enough? Is it practicable?

12.1 Selecting from the menu

If you’ve followed the steps in previous chapters you will have a menu of possible controls for each of the significant hazards previously identified. Many of the ‘conkers bonkers’ or ‘hanging baskets banned’ stories come about because an organisation treats the menu as an ‘all you can eat buffet’ and adds in every control they can think of. Alternatively, they ban something (conkers or hanging baskets) because they can’t think of a better system of management.

Chapter 11 describes systems for prioritising controls according to long-term effectiveness, and the necessity of sometimes choosing controls for short-term expediency. Sticking with our restaurant analogy, how do we know when we’ve ordered enough dishes to satisfy our appetite, without ordering so much that food will be wasted? How do we know we have controlled the risk ‘so far as is reasonably practicable’?

In this chapter we’ll bring together what we know about ‘reasonably practicable’ (RP) and consider some examples to help distinguish between not enough, enough and too much. The key points we’ll consider are:

- The HSE advice on RP implies a balancing act (but this might not be true).

- You have to apply prescriptive legislation before you think about what is reasonably practicable.

- RP implies something more than a balance, but something less than a ‘gross disproportion’

- The difficulties of valuing (and not valuing) life.

- Practicability is not fixed, and is affected by tolerability and technology.

- Legal cases tend not to involve a delicate weighing of cost, time and trouble against a measure of risk.

- You need to follow good practice (and sometimes best practice).

- As well as official and industry guidance, you should ask workers what works.

In our last section we’ll return to selecting from the menu, so if you want the quick read version, go there directly.

12.2 A balancing act?

In the second part of the description of ‘Control the risks’ the HSE offer a description of reasonably practicable.

What reasonably practicable means:

Put the controls you have identified in place. You’re not expected to eliminate all risks, but you need to do everything ‘reasonably practicable’ to protect people from harm. This means balancing the level of risk against the measures needed to control the real risk in terms of money, time or trouble.

So is deciding on which items to select from your menu simply a matter of weighing the cost of each control against its benefits? Is there a mathematical equation which will always come up with the right answer to keep people safe, and if that fails, to keep organisations un-fined and managers out of jail? It might not surprise you to learn the answer is a clear no, as we shall see.

12.3 Reasonably practicable does not apply to prescriptive legislation

If something is required by legislation, you must do it however impractical you might think it is. The requirements of the Control of Asbestos Regulations (CAR) mean you cannot argue that an asbestos survey is too expensive before a refurbishment of an older building. The Lifting Operations and Lifting Equipment Regulations (LOLER) mean that you can’t risk assess your way out of a six-monthly statutory inspection of a passenger lift, just because it isn’t used very often. See Table 6.1 in Chapter 6 for more examples of prescriptive rules about controls which must be applied before you consider reasonable practicability.

Sometimes, prosecutors or plaintiffs can find legislative requirements the defendant might not have considered in advance. Take for example the civil case of Wallace v Glasgow City Council (2010). In the initial case, the judge ruled that it was reasonable that the school management would not have considered what controls might be required to protect Mrs Wallace from falling from a toilet seat. However, on appeal, the plaintiff’s legal team cited the prescriptive requirements of the Workplace (Health, Safety and Welfare) Regulations 1992 requiring that “rooms containing (sanitary conveniences) are adequately ventilated” and that where windows could be open, then the manner of opening should not expose “any person performing such operation to a risk to his health or safety.”

Note that a 2013 Act changed the ability of the plaintiff to use a breach like this to claim compensation, with some exceptions.

However, the lesson remains: you need to follow the law before you consider what is reasonably practicable. In the Glasgow case it would have been practical for the school to provide a window-opening pole (especially as the school already had one in the caretaker’s room).

12.4 Gross disproportion

In Chapter 5 I quoted the 1949 case against the (UK) National Coal Board, illustrated with a set of scales. It’s worth looking at that quote again:

‘Reasonably practicable’ is a narrower term than ‘physically possible’ … the quantum of risk is placed on one scale and the sacrifice involved in the measures necessary for averting the risk (whether in money, time or trouble) is placed in the other, and that, if it be shown that there is a gross disproportion between them – the risk being insignificant in relation to the sacrifice – the defendants discharge the onus on them

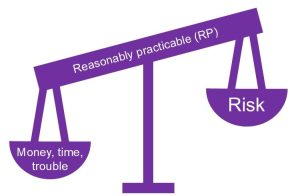

Figure 12.1: The balance of sacrifice and risk

The HSE recognises that ‘gross disproportion’ is a difficult concept. By 2024 (as I write this chapter) the original ‘ALARP at a glance’ page has expanded to a 3000-word description. Hardly ‘at a glance’. Amidst these 3000 words are a couple of useful examples, illustrating what is ‘grossly disproportionate’ and what is ‘proportionate’:

- To spend £1m to prevent five staff suffering bruised knees is obviously grossly disproportionate; but

- To spend £1m to prevent a major explosion capable of killing 150 people is obviously proportionate.

In these definitions there is an admission that only ‘obvious’ examples have been provided. There are no less obvious examples of what would be ‘a bit disproportionate, but not so much as to give you a reason not to do it.’

The HSE provides more details of how to do cost-benefit analysis on its website, but discourages most organisations from looking at it. It might be relevant if you run a nuclear power station or a chemical plant, but for occupational health and safety, your efforts are better spent elsewhere.

If you still think it can be calculated, let’s look at the advice the HSE provide.

Something is reasonably practicable unless its costs are grossly disproportionate to the benefits. Put simply if costs divided by benefits are greater than the disproportion factor then the measure can be considered not worth doing for the risk reduction achieved. DFs that may be considered gross vary from upwards of 1 depending on a number of factors including the magnitude of the consequences and the frequency of realising those consequences, ie the greater the risk, the greater the DF.

This was previously accompanied by this equation (as of 2024 the equation seems to have been removed):

DF is the ‘disproportion factor’. In relation to the nuclear industry, the HSE mention different disproportion factors for different situations. A DF of 3 for workers, a DF of 2 for low risks to members of the public, and up to 10 for high risks.

So the equation would indicate that if the costs of a measure were more than ten times the benefits, it would be disproportionate.

A worked example is provided using the higher DF of 10, where the financial value of harm to workers over a period of 25 years is around £9,300, meaning that expenditure on controls below £93,000 (that is, ten times the human cost) is reasonably practicable.

But how do you put a financial value on harm to workers?

12.5 A price on safety and health

The morality around putting a price on life is very difficult. Many professionals argue that you can’t put a price on safety, or health. But think about this:

Ask yourself:

The board of an organisation has two proposals in front of them. They both cost £500,000 and there is only a budget for one project. They want your opinion on which one to approve. Project A will eliminate a hazard that your figures show is causing at least five workers to take early retirement every year. Project B will eliminate a hazard that results in one early retirement every five years. Which one will you support?

If you chose Project A, you’ve just used economics as a decision tool for health and safety.

A second argument for placing a value on life and on health is that without a monetary value, health and life safety might not be valued at all. See Box 12.1.

Box 12.1: The problem of not putting a figure on the value of life

In 1949, the US Air Force commissioned the RAND Corporation to design a first strike on the Soviets. RAND developed a complicated model which included a fixed budget for procurement, operation and fissile material, and considered the costs of different aircraft types. After crunching hundreds of equations for over 400,000 configurations of bombs and bombers they came to the conclusion that the most cost-effective solution was not to use modern, expensive turbojets, with all the protection they provided to aircrew, but to use many more, cheaper, more vulnerable propeller planes. Some would act as decoys, defenceless and carrying no nuclear weapons. Loss of planes and personnel would be high, but the bombing objective could be met. They placed no value on the loss of human life.

If you are having difficulty getting support to implement controls you know are needed, you might need to make a business case which includes financial values. Trying to sell the controls with the promise of avoiding an expensive accident which, so far, has never happened might not be effective. Showing you understand all costs associated with your proposed control will give the people holding the purse strings more confidence in your decision-making.

Table 12.1 suggests some relevant costs and benefits to include in a business case.

Table 12.1: Financial costs and benefits of a control

| Costs | Benefits |

|---|---|

| Purchase of equipment, tools etc Labour eg to install Maintenance Training for new process | Reduced budget for PPE Reduced training budget (if you no longer need PPE, you won’t need to train people to use PPE) Lower energy costs of new equipment Efficiency improvements (eg to reducing manual handling) Quality improvements Ability to meet targets (eg reducing breakdown maintenance by putting more resource into preventative maintenance will reduce downtime and could avoid customer penalties for late delivery) |

However, while this is useful for your business case, it won’t always help you to argue that a control isn’t practicable. The image of the scales implies that risk, cost, time and trouble can all be measured accurately with the same unit. A recipe for pastry requires half the amount of fat as there is flour. Whether making a single pie or enough for a restaurant I can compare these commodities easily on a single axis of measurement, such as grammes or ounces.

Table 12.2: Example calculation

| Cost of new equipment | Benefits of new equipment | ||

|---|---|---|---|

| Purchase cost: £100,000 | Running costs: £10,000 / year for ten years = £100,000 | Employee savings: £30,000 x 10 years = £300,000 | Quality improvement: £20,000 x 10 years = £200,000 |

Total cost: £200,000 | Total benefits = £500,000 |

||

Net change: | £500,000 – £200,000 = £300,000 | ||

A management-driven cost-benefit analysis (CBA) of a proposed change might try to place a currency value (let’s say, £) on each element. A new piece of equipment will cost £100,000 plus £10,000 a year to maintain and run. It will improve quality with fewer employers to run it. The employee savings are £30,000 a year, and the quality improvement reduces wastage by £20,000 a year. The equipment is expected to last for ten years. Table 12.2 shows an easy calculation.

A more detailed calculation would show that the machinery ‘pays for itself’ by the third year. A real CBA would take account of more factors, including inflation, but all of these can be calculated with a financial value.

Measuring harm in £ is a much more difficult process. The HSE give some values for the benefit of preventing harm.

For example, just over £1.3 million to prevent a fatality (twice this to prevent a cancer death), £200k for a disabling injury, and £300 for a minor cut. These figures are based on data from 1995, so woefully out of date. More recent Department of Transport values suggest a value of just over £2.4 million per fatality, and £270k for a serious injury (2023 figures available in 2024 – check the latest figures if you intend to use them).

To do the calculation as well as these values you need:

- The probability of the hazardous event that you wish to avoid. Not just on a scale from low to high, or even from 1 to 5. You need a probability like ‘1 x 10-6 per annum’ (that is, one in a million years) or ‘1 x 10-2 per event’ (one in one hundred events).

- If the event occurs, how many fatalities and injuries of each severity will there be? You might need a range of probabilities for a range of outcomes – for example, 10% chance of a death, 75% chance of a major injury, 15% chance of a minor injury. And you’d need to be able to put a value on each injury type.

- What is the lifetime of the organisation and of the control? For example, the control might be effective for only ten years, or it might be a permanent solution but for a business with a lifetime of twenty years.

Only high-hazard industries such as chemical or petroleum storage and processing will have the data and the time to carry out this sort of calculation.

For occupational health and safety “reasonable practicability” and “gross disproportion” are not calculations.

12.6 Practicability is not fixed

On one side of the scales, our toleration of risk is affected by ethical and social considerations, not just the value of lives or health. Thirty-one people killed in a train crash on one day is a tragedy that echoes through the decades; yet more than this number die on UK roads each week without the same reaction.

If we acted on the numbers alone we would embrace nuclear power, genetically modified organisms and strangers talking to our children as they walk to school. Instead, we would stop parents driving their children to school in gas-guzzling vehicles, adding to harmful air pollution, road accidents and poor health through lack of exercise.

In Reducing risks, protecting people (R2P2, 2001) the HSE defines tolerability as ‘the willingness to live with a risk so as to secure certain benefits’. During the BSE (bovine spongiform encephalopathy) scare in the 1990s, many people avoided buying beef – until quality cuts of beef were cheaper than baked beans, at which point the willingness of people to live with the risk of BSE increased.

On the other side of the scales, the cost, time or trouble of implementing controls changes over time. New technologies make the control of a hazard so much cheaper that controls previously seen as impractical become increasingly practicable.

In 1974, when the Health and Safety at Work Act became law in the UK, it was reasonable for an organisation to have their training records on index cards and their checklists on paper. If the root cause of an accident was linked to a lost paper record, no prosecutor would have argued that an organisation should have held their records on a computer system.

If security was an issue on a work site in 1974, it wouldn’t have been reasonably practicable to use a film camera to capture moving images and then wait for the film to be developed to review an incident. CCTV systems expanded when video cassette recorders (VCR) made it practicable to record, watch, erase and re-record.

A modern company that had an accident which could have been prevented by computer records or CCTV cameras could not use the RP argument as a reason for not having the technology. Similarly, devices for detecting smoke, heat and carbon monoxide have become so cheap, no one can argue against their benefit.

This doesn’t mean that because one organisation in an industry has chosen to add additional protection in, all organisations in that industry must do so. But there can come a point where a control measure becomes broadly expected across that industry, and will be expected (considered RP) by the regulator.

Table 12.3 suggests some technologies to review (if you haven’t done already).

Table 12.3: Technology-based controls becoming practicable

| Technology | Hazards/ hazardous events it can control |

|---|---|

| Mobile phones with GPS, accelerometers and gyroscopes providing worker location and work-down alarms. | Hazards associated with lone-working |

| Sensors or computer vision (CV) to monitor worker posture | Manual handling or workplace postures which can lead to musculoskeletal pain |

| Sensors or CV to monitor vehicles | Vehicle collisions, vehicle-pedestrian collisions |

| Wearable air quality monitors | Exposure to hazardous gases or fumes, reduced oxygen levels |

| AI tools to spot possible gaps in risk assessments | The hazard of missing hazards in risk assessments! |

12.7 What legal cases show us

The HSE are clear that they aren’t looking for mathematical explanations of RP for most organisations outside of major hazard industries. Perhaps where something is ‘complex or novel’, but otherwise, the HSE just expect you to apply ‘existing good practice that has been established by a process of discussion with stakeholders to achieve a consensus about what is ALARP.’ Take a look at these prosecutions:

In 2022 two company owners of Greenfeeds Ltd (the company secretary and a director) were jailed, and the company fined £2 million, following two deaths in a confined space. The company was dissolved in 2023.

In 2023, two company directors from different companies were sentenced to 9 months in prison after five men died at a recycling site when a wall fell on them. Hawkeswood Metal Recycling was fined £1m, Ensco 10101 Limited £600,000.

Ask yourself:

Why were these organisations prosecuted and found guilty? Was it because they miscalculated ‘gross disproportion’ when deciding on the controls needed? Did they apply a disproportion factor of 7 instead of 10? Or was it because people died when widely accepted ‘good practice’ was not followed?

We looked at R v Chargot in chapter 11 in relation to the burden of proof. The conclusion here was that when harm has occurred, the employer (or other person responsible for the risk) must show that there was nothing else they could ‘reasonably’ have done. In an earlier case (R v Davies, 2002) an employee was killed by a reversing vehicle. The company run by Mr Davies had never used a banksman (or signaller) for reversing vehicles, and Mr Davies was in the work area when he asked the driver to move the vehicle. It isn’t mandatory to use a signaller, but if you can’t eliminate reversing or keep pedestrians out of vehicle movement areas, a trained signaller is standard good practice, so Mr Davies could not argue that it wasn’t reasonably practicable.

In a later case (R v AH Ltd and others, 2021) the defence tried to overturn R v Davies and R v Chargot. They argued that the introduction of sentencing guidelines in 2016 made it more likely that someone could go to prison if they could not prove they had done everything reasonably practicable. This could mean, they argued, that a defendant could go to jail even when reasonable doubt exists. The defence was unsuccessful, and it remains true that when someone is harmed the defence must prove that it wasn’t reasonably practicable to prevent the accident (or that the accident wasn’t reasonably foreseeable). This proof doesn’t involve equations about the cost of measures versus the benefit, let alone any ‘gross disproportion’ factor. If you can’t afford to follow good practice, you shouldn’t be in business.

One last case illustrates how difficult it is to quantify ‘money, time and trouble’ against risk. In a legal judgement on a civil case in 2006 (Peter Alastair Struthers-Wright V. Nevis Range Development Company plc), the judge dismissed the case made by an injured skier that the resort management should have labelled any dangerous features. Warning signs might have been cheap to put in place, but the judge recognised that placing warning signs at regular intervals along the summit ridge would be a disproportionate response to the risk, given the ‘natural beauty and attractiveness of the wilderness site’.

If beauty were a factor in calculating gross disproportion, where else might it apply? Can scenic cities justify open canals in their busy centres? Do we cherish our British railway heritage so much we could not bear to see platform edge protection? I’m in favour of a coastal path all the way around mainland Britain, but I don’t want to see a coastal fence all the way too.

This doesn’t mean we can manufacture a dangerous situation because it’s beautiful. Courts seem more likely to give the benefit of the doubt when the hazard is a natural feature, such as a lake or cliff. In 2012 Warwick Castle wasn’t allowed to use heritage as justification for not putting barriers on a bridge following the death of a visitor who fell off the bridge into the moat in 2007.

12.8 Good practice (and sometimes best practice) are the answer

Chapter 6 explained that you cannot use risk assessment to argue against the controls required by law. Similarly, if controls are recommended or advised by the regulator or an industry body as good practice, if you don’t do them and someone is hurt, you will need to be able to explain why you didn’t. The HSE are clear that the ‘cost-benefit’ approach:

cannot be used to argue against the implementation of relevant good practice, unless the alternative measures are demonstrated unequivocally to be at least as effective.

Deciding not to use a trained signaller for reversing vehicles could be defended if you showed that you had instead implemented a system (perhaps based on computer vision and wearable technology) that provided warnings to drivers and pedestrians when they were too close, and that this system eliminated the risk to a signaller, while providing protection at least as adequate.

If someone is harmed, and recognised good practice would have prevented the harm, it is unlikely that a UK court would accept a defence of reasonable practicability.

Table 12.4 provides some examples of where to find out about good practice, starting with the types of documents you find on the HSE website, but also looking at industry bodies.

Table 12.4: Examples of good practice

| Topic | Sources |

|---|---|

| Work at height | HSE working at height advice |

| Ladder Association guidance In particular: LA Code of Practice (July 2021) LA455 Safe Use of Ladders and Stepladders – a brief guide (July 2021, replaced INDG 455) Website advice on inspecting a ladder |

|

| Avoiding the broken links, the Access Industry Forum will point you towards other specialist bodies, depending on the equipment you use for work at height, eg MEWPS, towers or rope access | |

| Legionella | L8, Approved Code of Practice and guidance for the control of legionella bacteria in water systems. HSE advice in the three parts of HSG 274 |

| Detailed advice from CIBSE. TM13 Minimising the risk of Legionnaires disease |

|

| Fire | Start with Government advice: UK Gov advice on duties under fire safety legislation UK Gov advice on duties under S156 of BSA 2022 |

| UK Gov guides on risk assessment in different sectors. |

12.9 Ask the people doing the job

It is widely understood that the money, time and trouble argument does not work for an individual employee. If an organisation has risk assessments and procedures in place requiring employees to use a particular piece of equipment to do a task, the employee cannot use as an excuse that it was too much trouble to fetch the equipment.

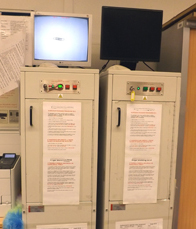

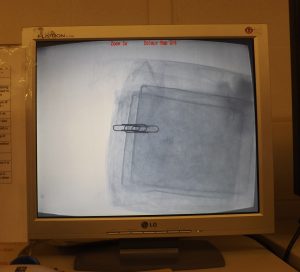

However, to determine if something is RP you should engage with the people who do (or will do) the work, and have to make the controls work. Too often I’ve seen controls in risk assessments (or documented in procedures) that will never happen. I mentioned in Chapter 4 [4.3] a client with an x‑ray machine in the post room to check incoming deliveries. The controls in the risk assessment described how if the member of staff thought a package was suspicious they should:

- Remove it from the X-ray machine

- Place it in a plastic container on the other side of the room

- Wash their hands in bleach in case they had become contaminated

- Call the emergency services.

Although the written procedure stuck to the front of the x-ray machine repeated these controls, when asked, the staff (fortunately) had a much more sensible process in mind:

- Leave the package where it is inside the x-ray machine and make sure the door is shut

- Ask a colleague to take a look at the image for a second opinion

- Call emergency services if any doubt remains

Washing their hands wasn’t practical, as there was no running water in the post-room. Fortunately, there was no bleach either, but appropriate wet wipes were provided after this. Since the x-ray machine was the most resilient container in the room, it made more sense to leave it inside than to move it, reduced the risk of further contamination, and allowed a second colleague, and where appropriate, the emergency services, to examine the parcel using x-ray without any further movement.

Other examples where asking the people doing the job has resulted in better (more practicable) controls:

- To improve ergonomics, an assessment in a factory proposed new chairs for workers who needed to sit lower than standard chairs allowed, in order to see the labels on racking they were sorting items into. The staff suggested adding labels at the top of the machine, where they could be seen when standing or using existing chairs.

- A permit-to-work system had controls which involved technicians gaining permission from one of only two senior managers to access lab spaces. The senior managers had to ask the lab managers before signing the permits. The technicians and lab managers complained that work was often delayed if the senior managers were unavailable or busy. The revised control was for lab managers to check and sign the permits. As they had a vested interest in getting the work done, they made sure they were available to check the worksite and approve the permits.

Sometimes, the controls suggested are practicable in some circumstances, and not in others. For example, asking people at an entertainment venue about their control of contractors process, it was clear that controls proposed for large projects, such as hour-long inductions and daily checks of work, would not be proportionate (inductions) or sufficient (daily checks) for many shorter projects. For a small piece of work it would be more effective for a host to provide a brief induction on the essentials as they walk the contractor to the work site, and either stay with them for the duration of the work (if it was less than an hour), or check in with them at frequent intervals during the day, making sure the contractor could get hold of them if needed.

12.10 Selecting from the hierarchy

Although you cannot risk assess your way out of prescriptive legislation, not all legislation is prescriptive. And while you can’t use an RP argument to avoid following good practice where you have no other effective controls in place, most guidance gives you options. You still have choices to make, but with a structure to make them in. As discussed in Chapter 11, there is a hierarchy of control. L108, the guidance on the Noise at Work Regulations, presents control options in this order:

- Eliminate or reduce the noise at source, eg with quieter tools and machinery, add damping material.

- Apply technical control measures, eg design and layout of workplace so people are further away from sources of noise, or have physical barriers between themselves and the noise.

- Apply organisational control measures, eg limit the duration and intensity of exposure to noise through appropriate work schedules.

- Where a risk remains, issue hearing protection.

- Provide hearing surveillance.

Maintenance, inspections and training are needed to monitor and enforce these controls.

Selecting options from this hierarchy is best done by a small team, considering the cost, timescales and effectiveness of each option. You often need different controls for different timescales. For example, you had noise measurements taken a few years ago, and levels were below the action level in the workshop. However, people have reported that it seems to be getting noisier. You select options from your menu as shown in Table 12.5

Table 12.5: Menu selection

| Timescale | Controls |

|---|---|

| Today | Explain to all staff that in the short-term they are required to wear hearing protection in the workshop. Make it clear that this is a short-term measure, but that it is very important that they co-operate. Check that everyone has access to appropriate hearing protection, and knows how to use it. |

| This week | Arrange for a further noise survey in this workshop (and any other border-line areas). Check arrangements for health surveillance of hearing to see if they are adequate, and review findings. |

| This month | The noise survey will help to prioritise, but you already know you should probably programme regular, repeated noise monitoring in border-line areas, and areas with existing noise controls. Whether the survey shows you have reached action levels or not, get some prices for adding screens, baffles or other measures to reduce the noise at source. |

| Over the next few months | Work with procurement to introduce a ‘buy quiet’ policy. Work with maintenance to review the impact of maintenance schedules on noise levels of machinery. For example, more planned maintenance could reduce noise, and reduce breakdowns, so have a benefit for productivity as well as hearing. |

12.11 Responsibility of manufacturers

Many of the most effective controls are out of the reach of the health and safety managers or worksite supervisors. I’d like to buy quieter equipment, but instead I have to provide hearing protection; I’d like to replace handheld tools with bench machinery, but instead I have to rotate workers to reduce vibration exposure; I’d like to use collaborative robots to support warehouse workers, but instead I train them to lift ‘properly.’

It doesn’t help that there is such limited enforcement of the responsibilities of manufacturers. There was one surprising use of section 6(1) of the Health and Safety at Work Act in 2023, when a manufacturer was fined for a design flaw which, in addition to an error in installation, led to the death of a worker four years after equipment had been installed.

In relation to noise, I’ve been tracking prosecutions against the Supply of Machinery (Safety) Regulations (SMR) since 2018, and haven’t yet seen a manufacturer prosecuted for failing to design and construct equipment to reduce airborne noise to the lowest level practicable.

12.12 Summary

So how do you know if you are doing everything reasonably practicable to ensure safety and health? Put away your calculator and scales, and ask:

- Is it a legal requirement? If yes, do it. If you can’t do it, or can’t afford to do it, then stop the activity.

- Is it in the guidance? If yes, start as high up the hierarchy as you can. If you can’t do something immediately, allocate some effort to demonstrating that what you are doing is equally as good, or towards working towards meeting that guidance. Can you live with the risk in the meantime?

- Are other organisations like you doing it? Will it help? Talk to the workforce.

- What will you say if there’s an accident? Ladders aren’t banned, but if there is an accident in a situation where you asked someone to use a ladder where you could have supplied a safer means of access, will you be able to defend the decision?

One problem is that many standard risk assessments don’t support the approach to controls advocated in this book. In Chapter 13 we will look at how we document controls, and how we monitor them.

You can use the Contact form to send me feedback. If you’d like to receive an email when I add or update a chapter, please subscribe to my ‘book club’ Alternatively, you can go back to the book contents page.