For and against: Manual handling training

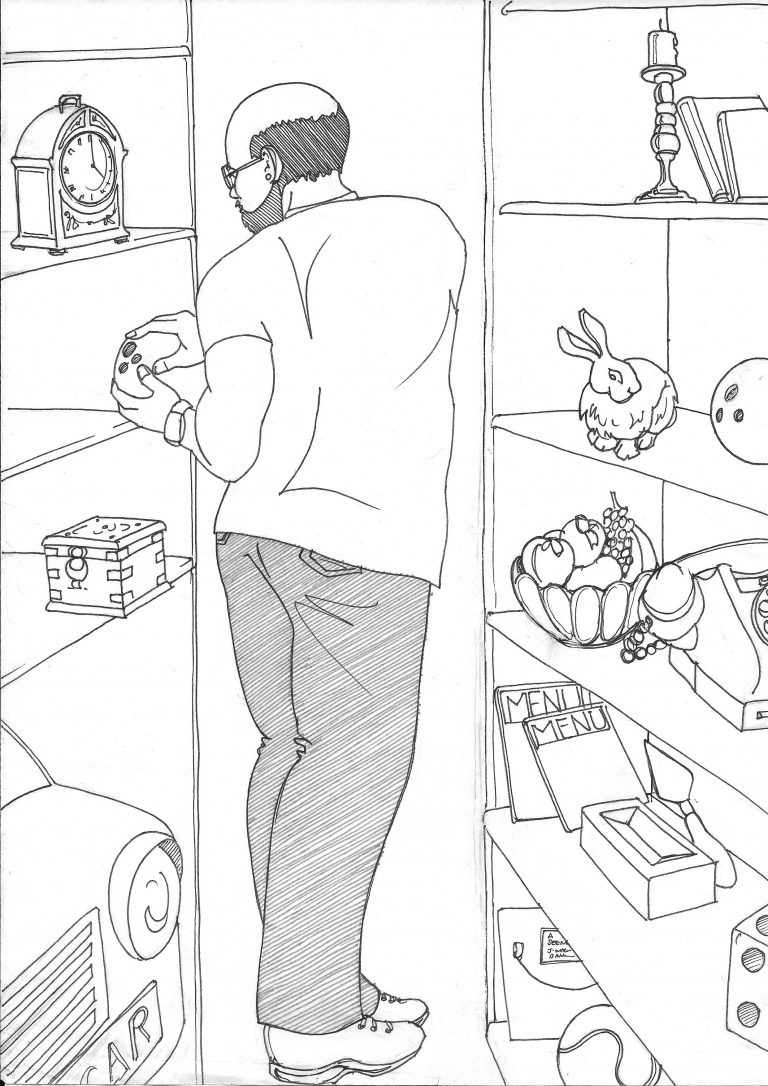

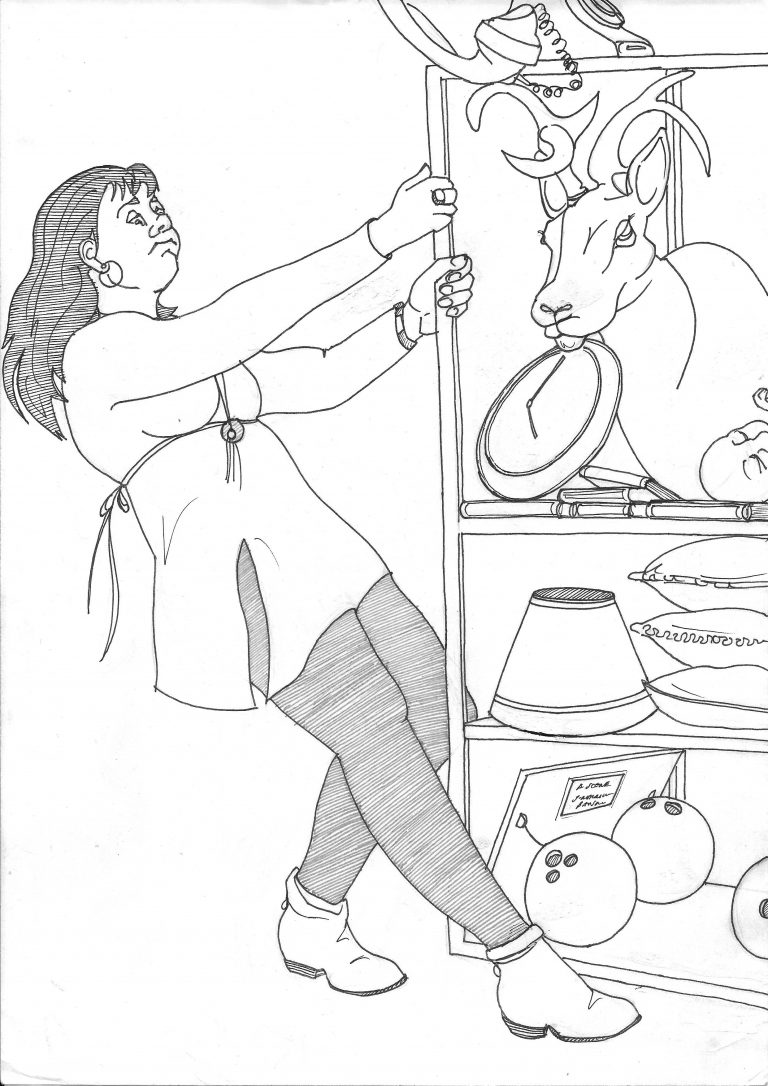

First published in Health and Safety at Work Magazine, October 2015. Illustrations for this version 2020.

Are handling courses worth the expense?

The restaurant chain Pizza Express learned the significance of manual handling tasks in 2011 when one of its employees was left tetraplegic by a poorly planned handling task. The grade II listed building which houses the group’s Kettner’s restaurant in London has a narrow, twisting staircase, up which four staff tried to carry a 168kg “hot cupboard” before it became stuck. In trying to free it, Kamil Pisarek fell backwards through a first-floor window to the pavement.

Imagine you are writing the risk assessment for a manual handling activity similar to that in the Kettner’s incident. You’ve agreed the likelihood and possible consequences and concluded that extra controls are required. You cheerfully write “provide manual handling training” in the controls column. Job done.

Manual handling training, however, is near the bottom of the control hierarchy; we know it is better to eliminate manual handling tasks than to train people. Though the risk should first be reduced through redesign of the task and environment, where manual handling operations remain, we need training to manage the residual risk. But does it work?

The highest standard of empirical research is the Cochrane Systematic Review, which covers all published research for a stated period, and comes to a conclusion based on the weight of evidence.

A 2010 Cochrane review by Stacy Clemes, Cheryl Haslam and Roger Haslam at Loughborough University published in Occupational Medicine confirms the findings of earlier reviews: manual handling training does not reduce the incidence of back pain or back pain disability when compared with doing nothing or doing something else.

An HSE-supported review, RR583, by the same authors came to a similar conclusion.

So, should you cancel your train the trainer manual handling course?

A quick trawl of “manual handling instructor” courses on the web reveals options from one to four days, with many promising to “reduce safety and litigation risks” or “avoid prosecution and litigation”.

Fear of litigation is the reason some organisations continue to invest in manual handling training. The Manual Handling Operations Regulations (MHOR) mention training only in schedule 1. In carrying out a manual handling risk assessment, the assessor is prompted to consider whether the job requires “special information or training for its safe performance”. This is low in the list of questions because if you have done all the things higher up (eliminated the manual handling or eliminated the hazardous elements of the task, such as twisting, holding loads away from the body or the possibility of falling from height while handling) no special training will be required.

Some manual handling courses last as little as two hours; less if you choose e-learning. If the training reviewed by Clemes et al was this brief and focused on avoiding litigation it is unsurprising it was unsuccessful.

Sam Woodhouse, training director for manual handling training provider Osteopaths for Industry (OFI), is concerned when an organisation’s main motivation is legal protection.

“The manual handling training market is saturated with generalist health and safety providers delivering training in ever shorter time periods, for ever lower costs,” says Woodhouse. “We have been asked to provide training in ways that we consider ineffective but, from an organisation’s point of view, ticks its compliance box.”

Core strength

Clemes et al suggest that strength and flexibility training “shows promise” since, according to one study, “most manual handling injuries are caused by a mismatch between a worker’s strength and the job requirements”.

But strength training could have the opposite effect, making people think they should be able to do a task by themselves rather than ask for help. Dr Alistair Bromhead, who heads a company bearing his name that provides manual handling courses, adds: “It is not true that most injuries are caused by a mismatch of individual strength and job requirements. For repetitive tasks, non-neutral joint positions are the issue rather than physical capability, and the bulk of long term back pain in the UK is thought to be cumulative rather than traumatic injuries associated with heavy weights.”

Two more encouraging directions suggested by Clemes et al get support from both Bromhead and Woodhouse. The first is to make the training more relevant to workers and the second is to reinforce training in the workplace.

Much manual handling training is based on moving boxes in a large classroom rather than awkward shaped pieces of equipment in a crowded plant room or a narrow staircase. RR583 found that 10 out of 30 training consultants interviewed did not even visit the work site before they started handling training.

If a refuse collector only ever moves bins, Clemes et al offer evidence that handling training will be more effective if it uses bins, not boxes. But if there is a lot of variety in the handling tasks it won’t be possible to train people on every one, and the benefits of task specific training are limited to that for which the individuals have been trained.

Breadth of training

One solution is to provide more background on the anatomy and mechanics behind handling so that trainers know how to adapt their training for novel situations. A large part of the Royal Society for the Prevention of Accidents’ (RoSPA) handling trainer’s course involves the student carrying out their own research on joints, levers, muscles and spine function.

Bromhead agrees that breadth is important: “One approach does not suit all. You need to explain the logic of good technique with some basic anatomy, and then demonstrate and

practise on a range of workplace loads, looking at different options: semi squat, golfer’s lift, one-knee down, team handling and so on.”

Woodhouse agrees that training should include the employee’s work tasks but to be effective “you must tell people why they should adopt different techniques, not just what they should be doing. We focus on explaining what is happening to the body when we lift”.

Assessment and job redesign

The RR583 research report argues that ergonomic training interventions “that include risk assessments, the observation of workers in their working environment, the tailoring of training to suit individual needs and the redesign of equipment and handling tasks can be effective in reducing the risk of manual handling injuries”.

Had a PizzaExpress risk assessment identified the low window on the staircase as a hazard, fitting bars to the windows would have been more effective at preventing the incident than training. Eliminating the need to move such heavy equipment would have been better.

Bromhead agrees that courses should cover manual handling risk assessment, not just training people to lift: “One of the key aims of our training is to equip trainees with the ability to identify higher risk tasks and suggest solutions (from up the hierarchy) that will reduce the risk at source. Technique training as a standalone measure is low down the control hierarchy. Good training should emphasise the importance of trying to avoid, automate and use handling aids where possible.” Woodhouse also sees risk assessment as crucial. “Manual handling training should,” he says, “be based on comprehensive risk assessments using tools such as MAC or ART.” (see box below.)

For RoSPA, relevance comes from a training needs analysis, with risk assessment as a supplementary activity. Associate trainer Melissa Lovell says: “RoSPA provides its manual handling trainer courses to enable employers to provide employees with health and safety information, instruction and training and, where relevant, supplementary information on manual handling risks and prevention. The RoSPA course is based on tailoring the training around a training needs analysis.”

MAC, ART and NIOSH

The manual handling assessment charts (MAC) tool is available on the HSE website to help identify high risk workplace manual handling activities. However, research commissioned by the HSE found no links between lost time due to lower back pain and the MAC scores, though there was a link with one parameter of the tool — hand distance from the lower back.

The Assessment of Repetitive Tasks (ART) tool, explained in INDG 438, is specific to repetitive tasks.

If you favour a numeric approach to assessing a task — and to weighting any design improvements you make — look at the Canadian NIOSH lifting equation.

Reinforced and empowered

Clemes et al and RR583 find that in many studies performance improves after training but that people return to previous (poor) methods of handling in time. Sometimes people don’t change because they cannot adopt the techniques learned in the classroom due to a lack of space, time, or support. RR583 concludes there is “considerable evidence that principles learnt during training are not applied in the working environment”.

Assuming that all the environmental factors do support the new behaviour, what else do you need to do?

“You won’t change 30 years of behaviour in 30 minutes,” says Bromhead. “Training is a starting point. After the training, it is essential to have workplace supervision and reinforcement.” Woodhouse agrees: “You’re very unlikely to change someone’s lifting habits during a three hour manual handling course. Providing refresher training every three years isn’t enough; trainers and supervisors need to know how to give feedback all year round.”

RoSPA also sees the importance of reinforcement. “Trainers need to develop mentoring and support in the workplace to reinforce good practice and discourage workers from reverting to old habits,” says Lovell.

Clemes et al reports on a study that finds “training should start with management and work down since it is pointless training the workforce if managers or supervisors do not have the same level of knowledge”. HSE funded research reported in RR379 and RR545, finds that supportive management is one of the most commonly cited facilitators of reduced handling risks, so training without empowerment will be ineffective. If the newly trained worker identifies that a shelf needs to be moved or a trolley purchased, resources need to be provided or the training will have been wasted. Bromhead identifies lack of management support as a reason for manual handling training failing to show results. “If good ideas for improvements are constantly rejected, trained handlers will become dispirited and revert to less safe behaviours,” he says.

Cloudy screen

Some organisations hope to meet their risk assessment requirement for handling training by sitting staff in front of a computer for 45 minutes to answer some multiple choice questions. E-learning cannot replace practical training. No studies looking at the effect of e-learning on manual handling behaviour have been identified, but what is available does suggest e-learning does not improve health and safety related behaviour.

A 2006 systematic review published in the journal Personnel Psychology found that web based learning had a small benefit over classroom approaches for learning facts but not for behaviour. A 2004 study published in the Journal of Safety Research found after computer based training for workers in a hospital food services department, employees’ knowledge grew, but so did the number of hazardous conditions, such as puddles on the floor.

The evidence suggests that off the shelf manual handling training is unlikely to be effective. Training must be one part of a manual handling operations management system, starting with a risk assessment and considering how to reduce the baseline risk by removing handling or redesigning loads.

The risk assessment is also the key to making the manual handling training hazard specific, teaching staff not just how to lift a box but how to risk assess their own work and that of colleagues dynamically and exchange behavioural feedback.